In my last post, I created a schematic for a RFM69HW breakout board. I am using this effort to increase my understanding of what we are covering in the Contextual Electronics class and understanding of electronic concepts/practical implementations. This post is the next step in the process of going from “gee – I could use a breakout board that did…” to “I am using a breakout board that I built.” As it is said: “give a man person a fish and you feed him them for a day; teach a man person to fish and you feed him them for a lifetime”

This post is dah BoM! Files for the schematic, net list, and BoM can be found on the bitknitting github repository.

Thanks to Those that Go Before

I continue to experience a sense of gratitude to the amazing community of knowledgable engineers who willingly share their knowledge. THANK YOU! I’ve never enjoyed learning so much (and I am getting better at realizing “Google is my friend!” 🙂 ).

It is important to take a moment and acknowledge these exceptional efforts.

- The folks I noted in my last post – plutonomore, Felix from lowpoweredlab.com, Adafriuit

- Chris Gammel – our very knowledgable and gifted instructor of Contextual Electronics. A course I would highly recommend if you are interested in turning your prototypes into PCBs and learning tons about electronics along the way.

- Chip – who provided actionable feedback on this post. His comment was on chip power dissipation. I added it when I discuss the part choice for the voltage regulator. Chip’s feedback is a big reason why I write these posts. More please!!!!

The Goal

The goal of this post is to associate parts with the symbols on the schematics. The key things I will be doing include:

- making sure there are accurate models of the chips. Getting the footprint as exact as possible regarding pad sizes of the components will be key to being able to solder a component onto a PCB.

- identifying and buying parts from digi-key.

The Process

Each step in the process:

- Start with the net list

- Associate footprints with schematic symbols

- Build the BOM

Is outlined below. I found the hardest task was finding a part. I used Digikey.com for all parts except the RFM69HW, which Digikey does not carry. Digikey has an overwhelming number of parts. Imagine a store where there are rows and rows of items – most of the same size – and you have to read the fine print – in this case a whole bunch of gobly gook within a data sheet for a part with words that make sense to the “been there, done that” electrical engineers – while trying desperately to narrow the search. It was very overwhelming. This is another area where Chris’s Contextual Electronics course was valuable. Chris went through many digikey.com shopping excursions with us. There is a lot to pick up from someone like Chris who has “been there, done that” AND can transfer that knowledge! The second hardest task is creating a footprint in the likely event that kicad does not have the footprint in its system. I am a n00b to standard SMT component footprints and am extremely glad Chris covered footprint sizes in several of the Contextual Electronics units. This document is helpful if – you are like me 5 weeks ago – 0805 does not mean anything to you.

I will continue using kicad . The goal is not to document how to use kicad to do the tasks that need to get done. The main ones for this post – using CVpcb and creating footprints – is covered in this tutorial. A PDF of the schematic and kicad files are located in the bitknitting github repository). The kicad CVpcb tool is used for associating the footprint of a part that I’ll find on digikey.com with a schematic symbol.

Start with the Netlist

The first thing I need to do is create a list of the schematic symbols and then map a footprint of a part to each symbol. This is done in kicad by generating a net list (This post by the Curious Inventor shows screen shots of a kicad net list). The net list is super important because it is the glue that binds the design (schematic) with reality (the PCB layout).

Associate Footprints with Schematic Symbols

The next step is to make sure each component found on the schematic has information on the placement of pads that will connect the component to the circuit. The criteria for my parts selection include:

- in stock

- inexpensive in quantities of 1

- SMT component

- it can do the job

- standard footprint with a size I have a chance of soldering correctly. Even the larger SMT footprints seem small to my eyes.

The following sections will go through each type of component using the contents of the BOM spreadsheet related to that type of component. I will use a BOM spreadsheet that I made in Google Docs to put the information on parts, part size, cost, and ordering URL. The BOM spreadsheet is located here within the bitknitting github repository.

Capacitors

Below are the entries for the capacitors in the BOM spreadsheet. Based on what I learned in the last post, I initially intended on using electrolytic capacitors for the 10uF caps. They are bigger, but heck – I thought the experts had spoken. Chris recommended ditching electrolytic and stick with ceramic during my fantastic 1:1. He noted electrolytic are more sensitive to temperature and voltage, they dry out over time, and they are bulky. Good enough for me! I am relieved that I can use 0805 sized 10uF caps. I watched Chris as he did a search on digikey.com. One of the filters I didn’t understand what the temperature coefficient. Chris chose X7R capaciors – which after viewing the excellent table 1 in this post, made sense. Although X5R capacitors were $.20 and X7R capacitors were $.30, I felt the extra range in temperature afforded by the X7R capacitor was worth it.

Here are my choice for capacitors:

| Component | MFG Name | MFG Part Number | Distributor Part Number | Package size | Quantity | 1 piece price | 1 piece subtotal | 100 piece price | 100 piece subtotal | 1000 piece price | 1000 piece subtotal | Distributor Part Number Link |

| .1u CAPACITOR | Kemet | C0805C104K5RACTU | 399-1170-1-ND | 0805 | 2 | 0.1 | 0.2 | 0.01 | 1 | 0.01 | 10 | http://www.digikey.com/product-detail/en/C0805C104K5RACTU/399-1170-1-ND/411445 |

| 1u CAPACITOR | Samsung | CL21B105KOFNNNE | 1276-1026-1-ND | 0805 | 1 | 0.1 | 0.1 | 0.0196 | 1.96 | 0.01785 | 17.85 | http://www.digikey.com/product-detail/en/CL21B105KOFNNNE/1276-1026-1-ND/3889112 |

| 10u CAPACITOR | Nichicon | CL21B106KOQNNNE | 1276-2872-1-ND | 0805 | 2 | 0.3 | 0.6 | 0.1236 | 12.36 | 0.07262 | 72.62 | http://www.digikey.com/product-detail/en/CL21B106KOQNNNE/1276-2872-1-ND/3890958 |

A YIPPEE! moment. The 0805 footprint is already in kicad.

Resistors

The schematic uses 2 resistors. I used the footprint size and then narrowed the search to the least expensive in quantities of 1. Here is what I ended up with:

| Component | MFG Name | MFG Part Number | Distributor Part Number | Package size | Quantity | 1 piece price | 1 piece subtotal | 100 piece price | 100 piece subtotal | 1000 piece price | 1000 piece subtotal | Distributor Part Number Link |

| 470 ohm RESISTOR | Panasonic | ERJ-6GEYJ471V | P470ACT-ND | 0805 | 1 | 0.1 | 0.1 | 0.0149 | 1.49 | 0.00544 | 5.44 | http://industrial.panasonic.com/www-cgi/jvcr13pz.cgi?E+PZ+3+AOA0001+ERJ6GEYJ471V+7+WW |

| 10K ohm RESISTOR | Stackpole Electronics Inc | RMCF0805JT10K0 | RMCF0805JT10K0CT-ND | 0805 | 1 | 0.03 | 0.03 | 0.0088 | 0.88 | 0.0032 | 3.2 | http://www.digikey.com/product-detail/en/RMCF0805JT10K0/RMCF0805JT10K0CT-ND/1942577 |

ConnectorsI am not surprised about the low price given how common resistors are in a circuit. I am surprised in the difference in cost between the two resistors.

Connectors

The schematic uses three types of connectors:

- a 7 pin connector in which a male header will be soldered on so that the pins on the header will connect the breakout board to the breadboard. This isn’t an actual part – but rather througholes on the breakout board. This is similar to how most breakout boards that sit on a breadboard are done.

- Test points. Each test point needs a part.

Here was what I originally chose for test points off of digikey:

| Component | MFG Name | MFG Part Number | Distributor Part Number | Package size | Quantity | 1 piece price | 1 piece subtotal | 100 piece price | 100 piece subtotal | 1000 piece price | 1000 piece subtotal | Distributor Part Number Link |

| TEST POINTS | Harwin Inc | S1751-46R | 952-1478-1-ND | http://www.digikey.com/product-detail/en/S1751-46R/952-1478-1-ND/2264564 | 9 | 0.29 | 2.61 | 0.1888 | 18.88 | 0.13068 | 130.68 | http://www.digikey.com/product-detail/en/S1751-46R/952-1478-1-ND/2264564 |

After bumbling around with test point parts on digikey and talking with Chris, I decided to use 22 AWG gauge solid copper wires as a test point. By doing so, $2.61 is shaved off the prototype boards and this style is what I am used to.

Each test point will be a through hole on the PCB. I’ll solder in a different color wire in each, then connect the ends to probes. For example, I’ll connect the MISO/MOSI/CS/CLK lines to the MISO/MOSI/CS/CLK probes of my logic analyzer.

Using Wires for Test Probes

I’ll remove the test points after I get a few PCBs fabricated – once I feel comfortable that the circuit is working.

- A hole for a piece of copper wire acting as an antenna. There is no physical part. It is just a hole in the board.

Voltage Regulator

As I discussed in the last post, I will use the MCP1703:

| Component | MFG Name | MFG Part Number | Distributor Part Number | Quantity | 1 piece price | 1 piece subtotal | 100 piece price | 100 piece subtotal | 1000 piece price | 1000 piece subtotal | Distributor Part Number Link |

| VOLTAGE REGULATOR | Microchip Technology | MCP1703T-3302E/CB | MCP1703T-3302E/CBCT-ND | 1 | 0.65 | 0.65 | 0.41 | 41 | 0.41 | 410 | http://www.digikey.com/product-detail/en/MCP1703T-3302E%2FCB/MCP1703T-3302E%2FCBCT-ND/1776945 |

A YIPPEE! moment. Kicad has the footprint for the SOT23-A sized chip. One less part to go cross-eyed attempting to exactly match the dimensions of the part’s pads and placement in the footprint modeler.

Follow up: Chip commented:

Your selection of the 1703 in the SOT-23A case has a more limited power dissipation. That case has a high thermal resistance which in English that means that the SOT-23 will get hotter for a given load current than some of the other cases. Probably not a problem if your only application is to wake up once a minute take a reading, send a packet and then go back to sleep.

If you might use your breakout board in some more continuously transmitting application the SOT-23 might not cut it. Consider the SOT-223 case instead. It is five times as efficient at heat dissipation. For detailed descriptions see section 6.2 of the 1703 datasheet.

Felix had a counter reply:

I’ve not ever seen any heating or smoke out of that regulator in my own practice. Some people reported heating but I suspect they misused it or shorted the outputs (which WILL cause heating).

Wireless programming for instance is very RF intensive for a period of 20-30 seconds or even more depending on the sketch size. And there is no heating. So it’s a bit of a myth that the SOT23A is a bad choice. If it were, I would have replaced it over the several revisions of Moteino.

An aspect I love about community learning! Folks like Felix and Chip that have “been there, done that”. They come from a different context and have different experiences to share.

Level Shifter

Also discussed in the last post was the part for the level shifter:

| MFG Part Number | Distributor Part Number | Footprint | Quantity | 1 piece price | 1 piece subtotal | 100 piece price | 100 piece subtotal | 1000 piece price | 1000 piece subtotal | Distributor Part Number Link |

| 74LVC245ADB,118 | 568-2274-1-ND | SSOP20 | 1 | 0.44 | 0.44 | 0.2793 | 27.93 | 0.0033 | 3.3 | http://www.digikey.com/product-detail/en/74LVC245ADB,118/568-2274-1-ND/946736 |

A YIPPEE! moment. Kicad has the footprint for the SSOP20 sized chip.

RFM69HW

Last – but certainly not least – is the star of the breakout board, the RFM69HW:

| Component | MFG Name | MFG Part Number | Distributor Part Number | Footprint | Quantity | 1 piece price | 1 piece subtotal | 100 piece price | 100 piece subtotal | 1000 piece price | 1000 piece subtotal | Distributor Part Number Link |

| IN-HOME WIRELESS (@433MHz) | HopeRF | RFM69HW-433S2 | RFM69HW-433S2 | http://www.hoperf.com/upload/rf/RFM69HW-V1.3.pdf | 1 | 3.85 | 3.85 | 3.85 | 385 | 3.85 | 3850 | http://www.hoperfusa.com/details.jsp?pid=136 |

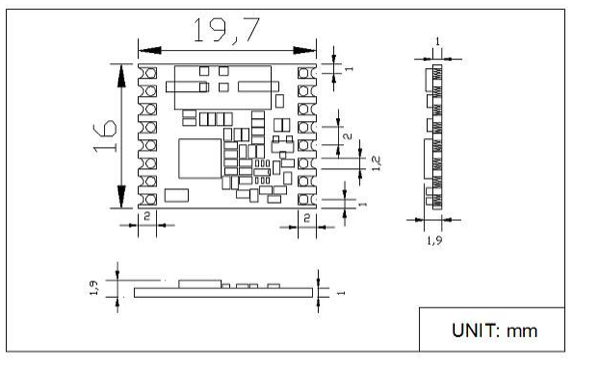

I put a link to the data sheet under the footprint column because the RFM69HW has a unique footprint:

Creating a footprint for the RFM69HW has brought up a concern. There are many different in-home wireless parts. They don’t speak with each other. In particular, the RFM69HW is not sell in the volume to make me feel comfortable that the part will be around for a few years. HopeRF has had many chips before this. I need to find out how long the company has been around, what has been the lifespan of their other chips, and details about distribution in the U.S. Right now I buy RFM69HW chips from Anarduino. The cost is lower than other places and the service has been excellent. With that said, I have no idea if this distributor will be around in the future. This is something I will look into. For now, I will continue to use the RFM69HW as the in-home wireless solution.

Let’s Go Shopping

While not quite as much fun as shopping at Adafruit, I had a grand time putting parts into my shopping cart. I ended up getting enough parts for 4 boards. I figured my soldering skills would kill at least one – who am I kidding? More than one….Also, I will receive 3 PCBs when I order from OshPark. Here’s my digikey shopping cart:

Next I hopped over to Anarduino.com and ordered 3 additional RFM69HW-433 MHz chips. I already have one from earlier tinkering that I’ll repurpose to complete the boards.

That’s a Wrap

I found part selection to be tedious. The data sheets don’t make this task any fun at all! Each one with their own style. Each one with particular criteria to pay attention to. I can tell it will be awhile before I feel comfortable that I am picking the “best” part for the job. At this point, I am going for “it works”. Chris and his Contextual Electronics course continue to be extremely valuable on my journey to make this breakout board.

All files – schematics, BoM, net list are available on the bitknitting github repository.

What’s Next

I’m getting to the fun stuff! This week I’ll be laying out the parts in kicad’s PCB tool – PCBnew – and drawing the traces. More on that in my next post!

Thanks for reading this post. Please find many things to smile about.